- Product Description

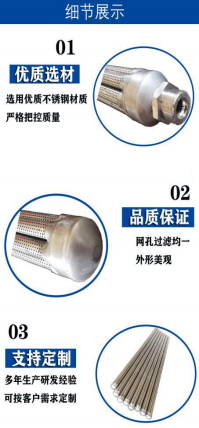

CVZS series fully automatic candle filter cake layer filtration system is designed and developed to address the filtration difficulties in the industrial production process. The equipment operates in a fully enclosed manner, without leakage and causing no pollution to the environment; 3-249 filter elements can be integrated inside the equipment, with a unique structure, large filtration area, small size and high efficiency; the filter element adopts a compound plum blossom structure design, which can be backwashed in a pulsed manner and is easy to remove the cake; the entire process of filtration, drying, cake washing, cake removal and slag discharge is automated, which reduces labor intensity and is easy to operate. It has five major functions: direct filtration, slurry concentration, cake recovery and cake washing, and can be applied to a variety of special filtration occasions such as high impurity content, viscous liquids, extremely high precision and high temperature.

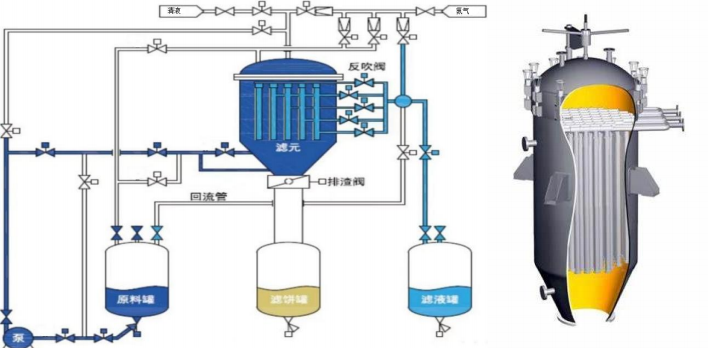

Working Principle:

CVZS series fully automatic candle filter cake layer filtration system uses gas as power, fully automatic operation, and fully enclosed filtration. The filter structure is combined with multiple unique compound plum blossom structure filter elements. When filtering, the slurry is pumped into the filter. The liquid phase in the slurry passes through the filter cloth and enters the center tube of the filter element to be discharged from the clear liquid outlet. At this time, the filter cloth is attached to the outer surface of the filter element support tube to increase the filtration area and help fix the filter cake. During pre-coat filtration, before the filter cake is completely formed, the discharged clear liquid returns to the raw material tank and is then sent to the filter for cyclic filtration until the filter cake is formed to meet the filtration requirements. A signal is provided to control the clear liquid to stop circulating, and the clear liquid is sent to the next process through the three-way valve for normal filtration. When the filter cake on the surface of the filter element reaches a certain thickness, a signal is provided to control the material to stop, and then the residual liquid in the filter is drained. After draining, a signal is provided to control the forward air inlet (compressed air, nitrogen or steam) to dry the filter cake, and then a signal is provided to control the reverse air inlet to backflush. At this time, the filter cloth on the filter element swells and becomes round, and the pulse vibration effectively shakes and peels off the filter cake. After a certain period of time, the backflush stops, and a signal is provided to open the filter slag discharge port for slag discharge. After the slag discharge is completed, the slag discharge port is closed, and the filter returns to the initial state before filtration, ready for the next round of filtration.

Product advantages:

Product advantages:

Reduce system operation costs; traditional filtering equipment requires a large number of staff to operate and maintain, the CVZS series candle filter cake layer filtration system adopts an intelligent control system, and the entire process of liquid inlet, filtration, liquid discharge, drying, back-blowing cake removal, slag discharge, and cleaning is automated, reducing the number of staff and reducing labor intensity. Traditional filtering equipment uses a large amount of filter cloth and consumes a lot of electricity. The CVZS series candle filter cake layer filtration uses multiple porous filter elements, which are easy to maintain and consume less filter cloth. There is no need for manual disassembly and cleaning; it adopts intelligent control and consumes only 150 watts of power, saving a lot of electricity.

Improve product yield: The CVZS series candle filter cake layer filtration system adopts fully enclosed filtration, eliminating the loss of products caused by running, bubbling, dripping and leaking. Because the filter cake of the filter cake layer is more evenly distributed than the special plate frame, the filter cake contains less liquid than the plate frame, and the obtained filter cake is drier, which greatly improves the product yield. The filter residue on the filter cloth of traditional filtration equipment is difficult to fall off. The filter cake layer filter adopts a compound plum blossom structure skeleton, which makes it easier for the filter cake to fall off during gas backblowing, and the pulse number is controlled according to different materials. The cake removal rate can be greater than 98%, and the obtained filter cake yield is higher than that of the plate frame.

Improve product quality: According to national health standards, the air contains a large number of Escherichia coli, Staphylococcus aureus, Pseudomonas aeruginosa and other bacteria. Enterprise product filtration should avoid contact with air. Compared with traditional filters, the CVZS series candle filter cake layer filter system adopts fully enclosed operation, which isolates the contact between liquid and air and avoids product contamination. The candle filter cake layer filter uses multiple filtering technologies of liquid passing through filter cake, filter cloth and filter screen. The filter cake is evenly distributed on the filter element skeleton and remains stable. The obtained filtrate is more stable than the traditional filtering method, which improves product quality.

Product Inquiry

If you have any questions or needs, please leave a message or contact us, and we will reply to you as soon as possible.